Common Mistakes in Floor Shop Drawings—and How to Avoid Them

Floor shop drawings play a crucial role in the construction and installation process, serving as the blueprint for accurately translating architectural designs into reality. These detailed diagrams guide contractors, fabricators, and installers, ensuring that every component fits precisely and functions as intended. However, even minor errors in shop drawings can lead to costly delays, miscommunication, material waste, and structural issues.

From overlooked dimensions to unclear labeling, common mistakes in floor shop drawings often stem from a lack of coordination, rushed timelines, or insufficient review processes. Understanding these pitfalls is the first step toward avoiding them. In this guide, we'll explore the most frequent errors found in floor shop drawings and provide practical strategies to catch and correct them—before they impact your project.

What Are Floor Shop Drawings?

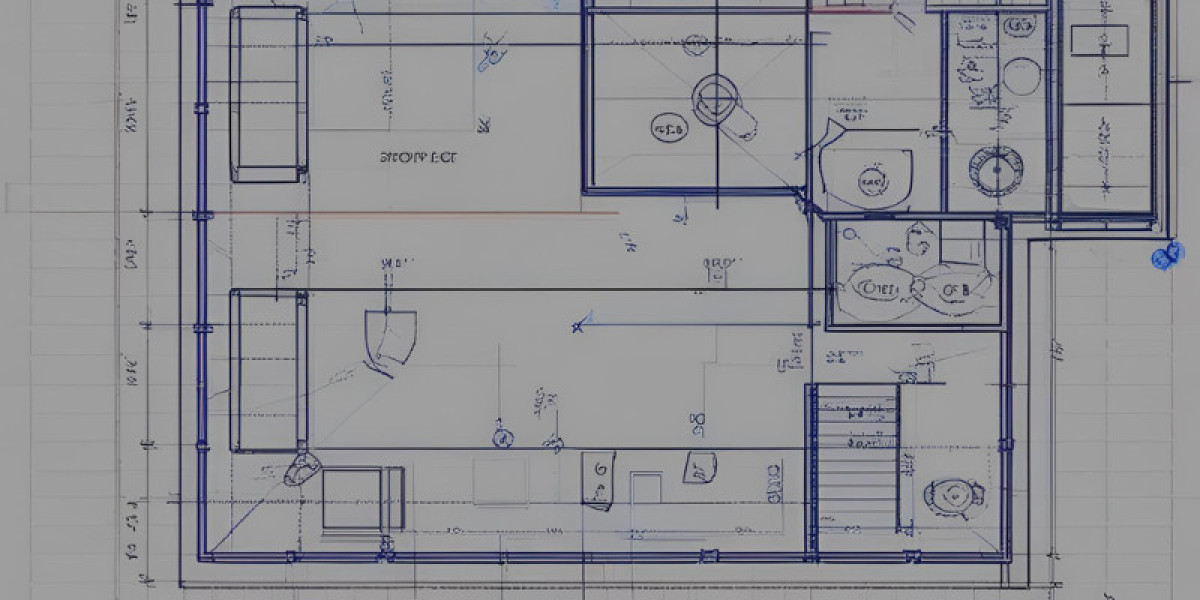

Floor shop drawings are detailed plans that show how the floors of a building should be made and installed. These drawings are used by construction workers, engineers, and architects to make sure the floor is built correctly. They include important information such as the floor layout, materials to be used, and how each part fits together.

Unlike regular floor plans, which show the general design, floor shop drawings focus on the technical details. They often show the exact sizes of floor parts, the placement of joints, and where different materials will go. For example, if a floor has tiles, the drawing will show how the tiles should be arranged and how much space should be between them.

These drawings are usually made by contractors or manufacturers after the architect finishes the main design. They are then checked and approved by the architect or engineer before work begins. This process helps avoid mistakes during construction.

Floor shop drawings are very helpful because they give clear instructions. They help workers understand what to do, which materials to use, and how to install the floor safely and correctly. This saves time, reduces waste, and ensures high-quality work.

In short, floor shop drawings are like a detailed guide for building the floors in a project. They are an important part of the construction process and help turn design ideas into real, strong, and beautiful floors.

Why Accuracy in Shop Drawings Matters

Accuracy in shop drawings is very important in construction and manufacturing. Shop drawings show the details of how things will be built, such as walls, windows, doors, pipes, and other parts. These drawings are used by workers to make and install parts of a building or a product.

If the shop drawings are not correct, many problems can happen. Workers might build something the wrong size or put it in the wrong place. This can cause delays, waste of materials, and higher costs. In some cases, wrong drawings can even make buildings unsafe.

Accurate shop drawings help everyone understand the plan clearly. They make sure that the work matches the design from the engineers and architects. When the drawings are right, workers can do their jobs faster and with fewer mistakes. This saves time and money.

Also, shop drawings are used to get approvals before building starts. If the drawings are not clear or wrong, they might be rejected. This can cause more delays.

In short, accurate shop drawings help the whole project run smoothly. They reduce mistakes, save money, and keep the work safe and correct. That is why it is so important to take time and care when making shop drawings. Every small detail matters, and getting it right from the start can make a big difference in the end.

Common Mistakes in Floor Shop Drawings

1. Wrong Measurements

One of the most common mistakes is using incorrect measurements. If the sizes of rooms, walls, or tiles are wrong, it can cause big problems during construction. Everything must be measured carefully and checked more than once.

2. Missing Details

Sometimes, the drawing does not include all the needed information. Important things like material types, thickness, or joint details might be missing. These small details help the workers understand how to build everything correctly.

3. Confusing Symbols

Floor shop drawings use symbols to show different things like doors, windows, tiles, or plumbing lines. If the symbols are not used properly or if they are not explained clearly, it can confuse the workers.

4. No Scale or Wrong Scale

Drawings must be made to scale, meaning the sizes in the drawing must match the real-life sizes when multiplied by a certain factor. If the scale is missing or wrong, everything could be built in the wrong size.

5. Overlapping Lines or Cluttered Drawing

If the drawing has too many overlapping lines or is messy, it becomes hard to read. Clear and clean drawings help workers understand the plan easily.

6. Not Following Design Changes

If the architect or designer makes changes to the design, the drawings should be updated. Sometimes, old versions are used by mistake, which leads to wrong construction.

7. Wrong Floor Levels or Heights

Mistakes in floor height or level markings can cause uneven floors, which can affect the whole structure and finishing.

8. Missing Notes or Instructions

Clear notes and written instructions are very important. Without them, workers might not know how to install certain parts correctly.

The End Note

In conclusion, floor shop drawings are essential tools in the construction process, serving as the detailed guide for translating architectural designs into tangible, functional floors. Accuracy in these drawings is paramount to avoid costly mistakes, delays, and safety issues.

Common errors such as incorrect measurements, missing details, confusing symbols, and failure to update design changes can lead to significant setbacks in a project. By ensuring that floor shop drawings are precise, clear, and thoroughly reviewed, construction teams can save time, reduce waste, and guarantee the successful completion of the project.

Vigilant attention to detail and careful coordination during the drafting process are key to avoiding these common pitfalls and achieving a smooth, efficient construction process.