As demand for recycled plastics continues to rise, pet flakes buyers have become a vital commodity across industries, from packaging to textiles. Whether you’re sourcing PET flakes for bottle-to-bottle recycling, fiber production, or thermoforming applications, the key to successful procurement lies in quality, consistency, and supplier reliability.

What Are PET Flakes?

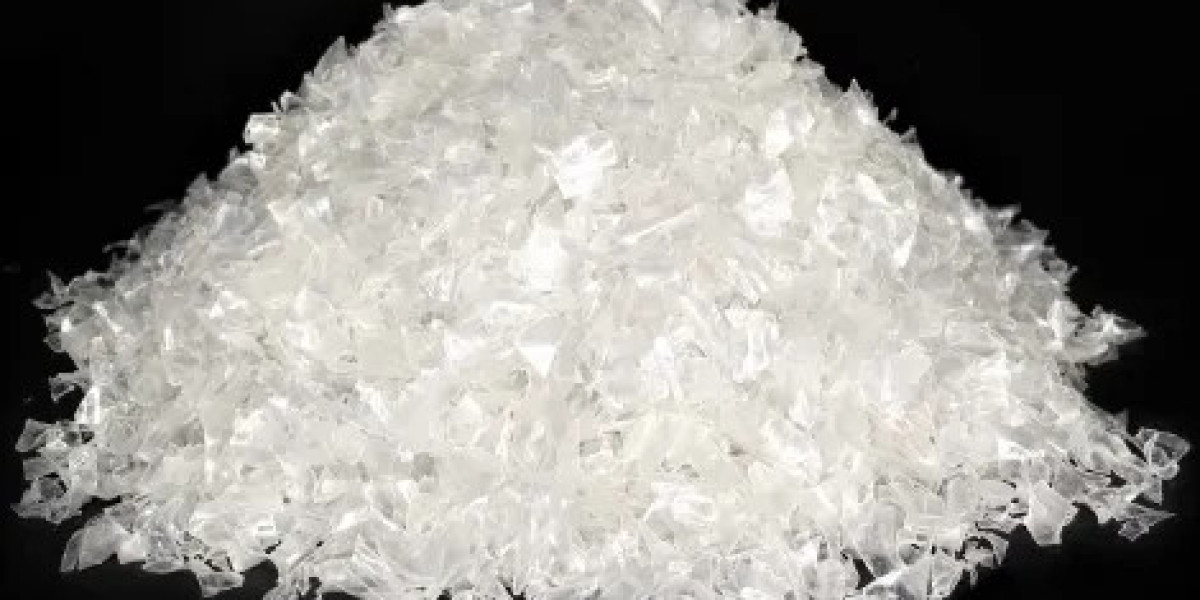

PET (Polyethylene Terephthalate) flakes are produced by processing post-consumer or post-industrial PET bottles and containers. The recycling process involves sorting, washing, shredding, and drying the plastic, resulting in clean, reusable flakes.

These flakes are used to manufacture a wide variety of products:

Food and beverage packaging

Textile fibers (like polyester)

Strapping and sheets

Non-food grade containers and components

Why PET Flake Quality is Crucial

For buyers, the quality of PET flakes directly affects the final product performance, production efficiency, and regulatory compliance. Here’s what to consider:

1. Purity & Contamination Levels

High-quality PET flakes are free from PVC, metals, labels, adhesives, and other polymers. Contaminants can disrupt manufacturing processes and cause costly defects.

2. Color Consistency

Clear and light blue flakes are often preferred in food-grade and bottle-to-bottle recycling. Mixed-color or green flakes are typically used for non-food applications.

3. Moisture Content

PET flakes must be thoroughly dried to avoid hydrolytic degradation during extrusion. Low moisture levels help ensure smooth processing.

4. Intrinsic Viscosity (IV)

IV determines the molecular weight and strength of the PET. A consistent IV is essential for applications like fiber production or thermoforming.

Key Tips for PET Flake Buyers

Know Your End Use – Food-grade applications demand stricter quality standards, including FDA or EFSA certification. Always match flake quality to your intended use.

Request Technical Data Sheets (TDS) – Work only with suppliers who provide clear documentation including specs for IV, moisture, bulk density, and contamination levels.

Audit Suppliers or Visit Facilities – If possible, inspect the production site to understand their sorting and washing processes. Clean, well-managed facilities often indicate higher quality output.

Prioritize Long-Term Partnerships – Building trust with reliable suppliers leads to better consistency, pricing, and responsiveness over time.

Global Supply, Local Impact

PET flakes are traded globally, but it's important to factor in local regulations, logistics, and recycling infrastructure. Some countries have stricter guidelines for importing recycled materials—be sure to stay compliant.

Final Thoughts

In a world moving toward sustainability, buyers have a crucial role in driving demand for high-quality recycled materials. Choosing the right PET flake supplier not only enhances your production but also supports the broader circular economy.

Whether you're an established recycler, a manufacturer entering the recycled plastics market, or a procurement agent looking to scale responsibly—know what you're buying, and buy smart.