A coolant shutoff valve is a crucial component used to control the flow of coolant in industrial systems. It ensures precise regulation, preventing overheating and maintaining efficiency. These valves play a vital role in various industries where thermal management is essential, such as automotive, manufacturing, HVAC, and machining. By automatically or manually stopping coolant flow, these valves contribute to operational safety, energy conservation, and equipment longevity. Companies like Proteus Industries Inc. specialize in manufacturing high-quality coolant shutoff valve tailored for different industrial applications, ensuring optimal performance and reliability.

What is a Coolant Shutoff Valve?

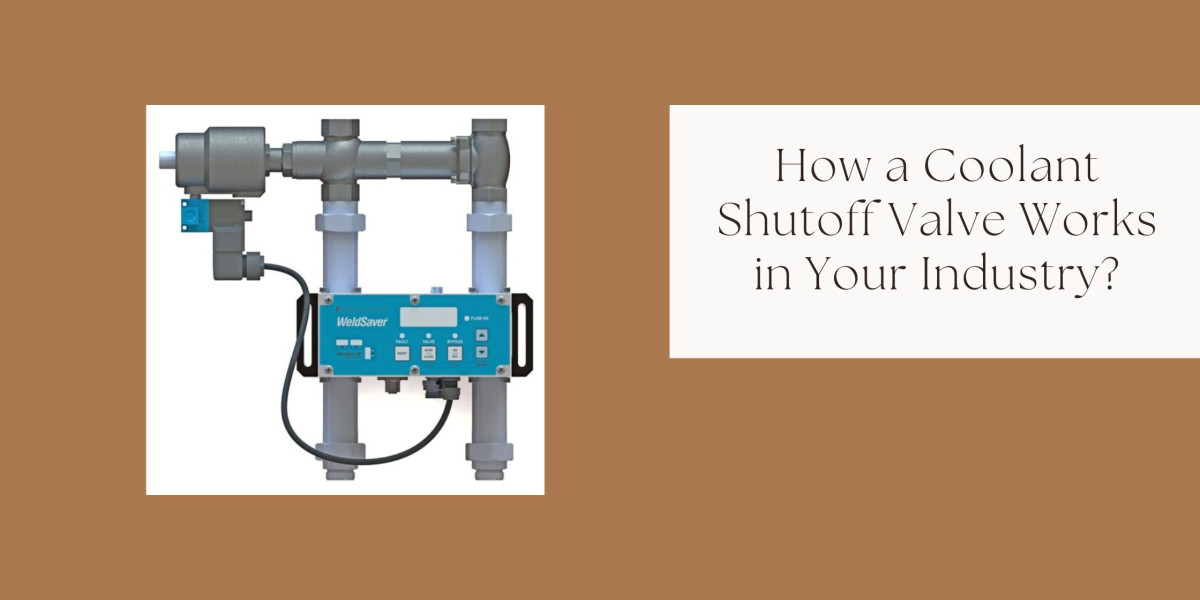

A coolant shutoff valve is a device designed to regulate or completely halt the flow of coolant within a system. It prevents coolant from flowing when not needed, reducing energy consumption and enhancing equipment protection. These valves typically consist of components such as a valve body, actuator, seals, and control mechanisms. Materials like stainless steel, brass, and high-grade plastics are commonly used to ensure durability and resistance to corrosion. Proteus Industries Inc. offers robust shutoff valves designed for high-precision applications in demanding industrial environments.

How a Coolant Shutoff Valve Works?

Coolant shutoff valves function by opening or closing in response to manual operation or automated controls. Manual shutoff valves require physical operation, while automatic valves use sensors, solenoids, or actuators to regulate flow based on system conditions. These valves help maintain optimal temperatures by preventing overheating and ensuring coolant is only used when necessary. By properly managing coolant distribution, they protect machinery from thermal damage, ensuring uninterrupted and efficient operations.

Key Benefits of Using a Coolant Shutoff Valve

- Prevents overheating and equipment damage – A coolant shutoff valve regulates temperature by controlling coolant flow, preventing excessive heat buildup. This protects machinery from thermal stress, reduces wear, and ensures consistent performance, avoiding costly repairs and operational disruptions.

- Enhances operational efficiency and energy savings – By minimizing unnecessary coolant flow, the valve optimizes cooling performance while reducing energy consumption. This leads to lower operating costs, improved resource management, and a more sustainable, efficient production process without compromising equipment functionality.

- Reduces maintenance costs and downtime – By preventing excessive wear and coolant waste, the shutoff valve extends equipment lifespan. It reduces the frequency of repairs and replacements, ensuring machinery remains operational for longer periods with minimal interruptions, leading to cost savings.

- Improves safety and equipment reliability – The valve prevents leaks, pressure fluctuations, and system failures, reducing the risk of workplace accidents and hazardous conditions. By maintaining optimal cooling, it ensures machinery operates smoothly, enhancing overall reliability and operational security.

Industry-Specific Applications

- Automotive Industry: Regulates coolant in machine cooling systems, enhancing machine performance and longevity.

- Manufacturing & CNC Machining: Controls coolant flow in precision cutting and metalworking operations.

- HVAC Systems: Manages refrigerant and coolant flow in air conditioning and refrigeration units.

- Power Plants: Plays a vital role in thermal management for large-scale energy generation.

How to Choose the Right Coolant Shutoff Valve for Your Industry?

- Material Selection: Opt for stainless steel or brass to prevent corrosion and ensure durability in demanding industrial environments.

- Temperature and Pressure Rating: Verify the valve can withstand your system’s specific temperature and pressure conditions for safe, efficient operation.

- System Integration: Choose a valve compatible with existing cooling systems to ensure seamless functionality and prevent operational disruptions.

- Reliable Manufacturers: Select trusted brands like Proteus Industries Inc. for high-performance coolant shutoff valves suited for industrial applications.

Maintenance and Troubleshooting

- Common Issues: Valves may leak due to worn seals, clog from debris, or fail to operate properly due to mechanical wear, corrosion, or improper installation, affecting performance and reliability.

- Preventive Maintenance: Regular inspections help detect early issues. Cleaning removes debris, while lubrication ensures smooth operation, reducing wear and prolonging the valve’s lifespan for optimal efficiency.

- Replacement Indicators: Persistent leaks, noticeable performance drops, or complete failure indicate valve replacement is necessary to maintain system functionality, prevent costly breakdowns, and ensure safety in operations.

Conclusion

Coolant shutoff valves are essential for maintaining efficiency, safety, and longevity in industrial cooling systems. Choosing the right valve involves considering material, operational parameters, and system compatibility. Regular maintenance ensures optimal performance and prevents unexpected failures. For high-quality coolant shutoff valves, Proteus Industries Inc. is a trusted provider, offering precision-engineered solutions for various industries.

FAQs

- How often should a coolant shutoff valve be replaced?

Typically, every few years, depending on usage and maintenance.

- What are the signs of a failing shutoff valve?

Leaks, inconsistent flow, and inability to open/close properly.

- Can a shutoff valve be repaired instead of replaced?

Yes, if the issue is minor, such as a seal replacement.

- What’s the difference between a coolant shutoff valve and a pressure relief valve?

A shutoff valve controls coolant flow, while a pressure relief valve releases excess pressure to prevent system damage.