Introduction

In the race toward sustainability, businesses and industries worldwide are rethinking their approach to waste management. One such innovation involves the use of bagasse, a fibrous byproduct from sugarcane processing. What was once considered waste, disposed of in heaps, is now emerging as an eco-friendly alternative to traditional materials. Bagasse, with its versatile applications, is not only reducing waste but also contributing to the shift toward greener, more sustainable production. This article explores the rise of bagasse from waste to a green solution, focusing on its industrial uses, environmental impact, and economic potential.

What is Bagasse?

Bagasse is the dry, fibrous residue left after extracting juice from sugarcane. For decades, it was considered an agricultural waste product, primarily burned for fuel in sugar mills or discarded in large quantities. However, with increasing global concerns about deforestation, plastic pollution, and the need for renewable resources, industries began exploring the potential of bagasse as a raw material.

This byproduct is highly abundant in countries that produce sugarcane, including India, Brazil, Thailand, and China. With sugar production rising globally, bagasse has become more available, leading to its recognition as a valuable resource for multiple industries. It’s composed of cellulose and hemicellulose, which give it strength, making it a viable alternative to wood pulp, plastic, and styrofoam.

Environmental Benefits of Bagasse

The shift to using bagasse addresses several pressing environmental challenges. Here's how bagasse contributes to sustainability:

Reduction in Plastic Waste: Plastic pollution is a major global problem, with single-use plastics causing massive environmental damage. Bagasse can be molded into disposable tableware, food containers, and packaging materials, serving as a biodegradable alternative to plastic. Products made from bagasse decompose naturally in a matter of weeks, unlike plastic, which can take hundreds of years to break down.

Decreasing Deforestation: Bagasse is increasingly used in the paper and packaging industry, substituting for traditional wood pulp. This helps reduce the need for tree logging, thereby contributing to forest conservation. Since bagasse is a byproduct, its use in paper production doesn't involve further exploitation of natural resources.

Lower Carbon Footprint: Bagasse-based products are manufactured with less energy than their plastic or wood counterparts. Moreover, bagasse can also be burned for energy generation, making it a source of renewable energy. Using bagasse as biofuel reduces reliance on fossil fuels, further minimizing carbon emissions.

Water Conservation: Paper production from wood requires substantial amounts of water and chemicals. In contrast, bagasse-based products consume significantly less water and use fewer toxic chemicals in the manufacturing process, leading to less environmental contamination.

Industrial Uses of Bagasse

The rise of bagasse has spurred innovation in various industries. Its versatility has allowed it to replace unsustainable materials in several applications, from packaging to energy production. Some of the primary uses of bagasse include:

Food Packaging and Tableware: The food industry is one of the largest consumers of bagasse-based products. The growing demand for eco-friendly, disposable tableware has led to an increase in the production of plates, bowls, cups, and cutlery made from bagasse. These products are heat-resistant, microwaveable, and can be safely used for both hot and cold food items.

Paper Industry: Bagasse is being used as a sustainable alternative to wood pulp in the paper-making industry. Bagasse-based paper requires fewer chemicals and is easier to bleach, producing paper that is not only eco-friendly but also of high quality. Companies like goldleaf India are tapping into this growing market by offering high-quality bagasse-based paper products.

Construction Material: Bagasse fiber is used in the production of eco-friendly building materials. It can be combined with other natural fibers to create particle boards and panels that are strong, durable, and cheaper than conventional materials. These boards can be used for furniture, ceiling tiles, and wall panels, helping to reduce the demand for timber and other non-renewable materials in construction.

Biofuel: Bagasse is also a renewable energy source. When burned, it produces electricity and heat, making it an excellent fuel for power plants. In countries like Brazil, bagasse is a key component in cogeneration plants that produce both electricity and heat, providing a sustainable energy source for sugar mills and nearby communities.

Economic Impact of Bagasse

The commercialization of bagasse products has not only benefited the environment but has also created new economic opportunities. Several bagasse product manufacturers have emerged, particularly in sugar-producing countries, where the byproduct is readily available. These manufacturers have been instrumental in promoting the widespread adoption of bagasse-based solutions, fostering the development of an eco-friendly industry.

For instance, goldleaf India, a major player in the field, has contributed significantly to the expansion of the bagasse industry. The company produces a range of eco-friendly packaging and paper products, catering to the growing demand for sustainable alternatives to plastic. Through their innovative approaches, manufacturers like goldleaf India are helping to scale the production of bagasse-based materials, making them more accessible and affordable to businesses and consumers alike.

Challenges in Bagasse Adoption

Despite the promising benefits of bagasse, its widespread adoption faces certain challenges:

Supply Chain Issues: Bagasse is produced primarily in sugarcane-growing regions, which may limit its availability in other parts of the world. Building a consistent supply chain for bagasse products can be challenging, especially in regions where sugarcane is not cultivated.

Cost of Production: While bagasse products are eco-friendly, they can be more expensive to produce than plastic due to the lack of large-scale manufacturing infrastructure. The costs associated with transporting bagasse from sugar mills to manufacturing facilities also add to the overall expense.

Consumer Awareness: Educating consumers about the environmental benefits of bagasse and promoting its adoption remains a hurdle. Many people are still unfamiliar with the material, which makes it challenging to compete against well-established products like plastic and styrofoam.

The Future of Bagasse

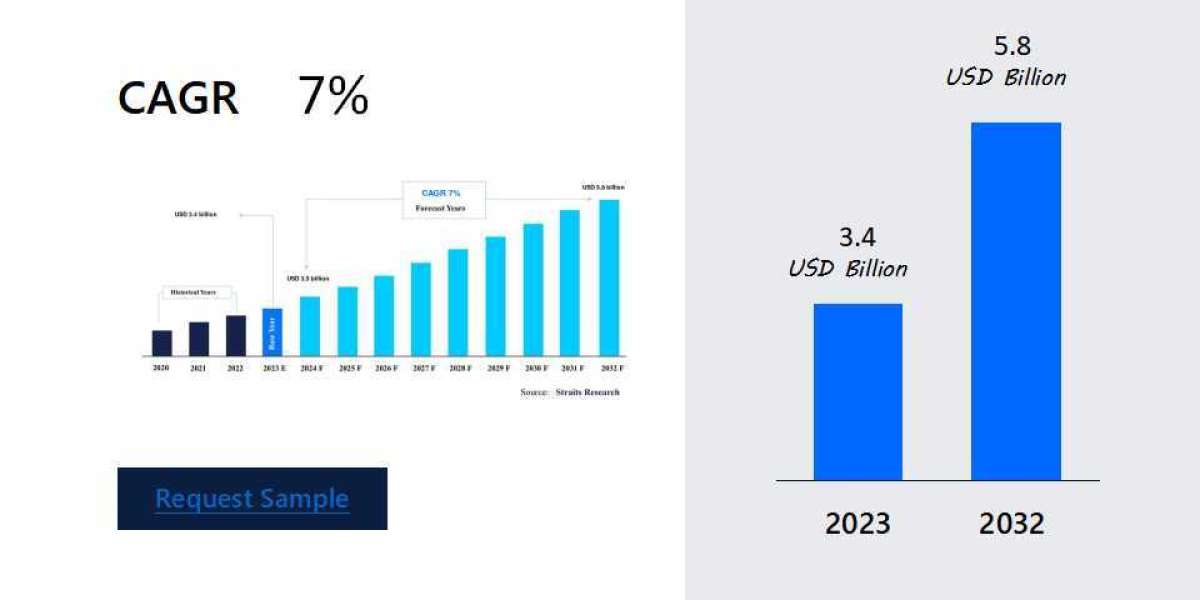

As environmental awareness grows and governments impose stricter regulations on single-use plastics, the demand for bagasse-based products is likely to increase. The development of better production technologies and expansion of bagasse supply chains will also help reduce the cost of these products, making them more competitive in the market.

Moreover, continued innovation in bagasse applications can further diversify its uses. From packaging to textiles and even bioplastics, the potential of bagasse is vast, and its role in a sustainable future is becoming more apparent.

Conclusion

Bagasse has transformed from an overlooked waste product into a pivotal material in the green revolution. Its versatility and environmental benefits make it a promising alternative to conventional materials like plastic and wood. As companies such as goldleaf India continue to invest in bagasse-based innovations, we can expect to see a surge in eco-friendly products made from this remarkable byproduct. With the right policies and consumer education, bagasse has the potential to play a critical role in mitigating environmental damage and promoting sustainability across industries.