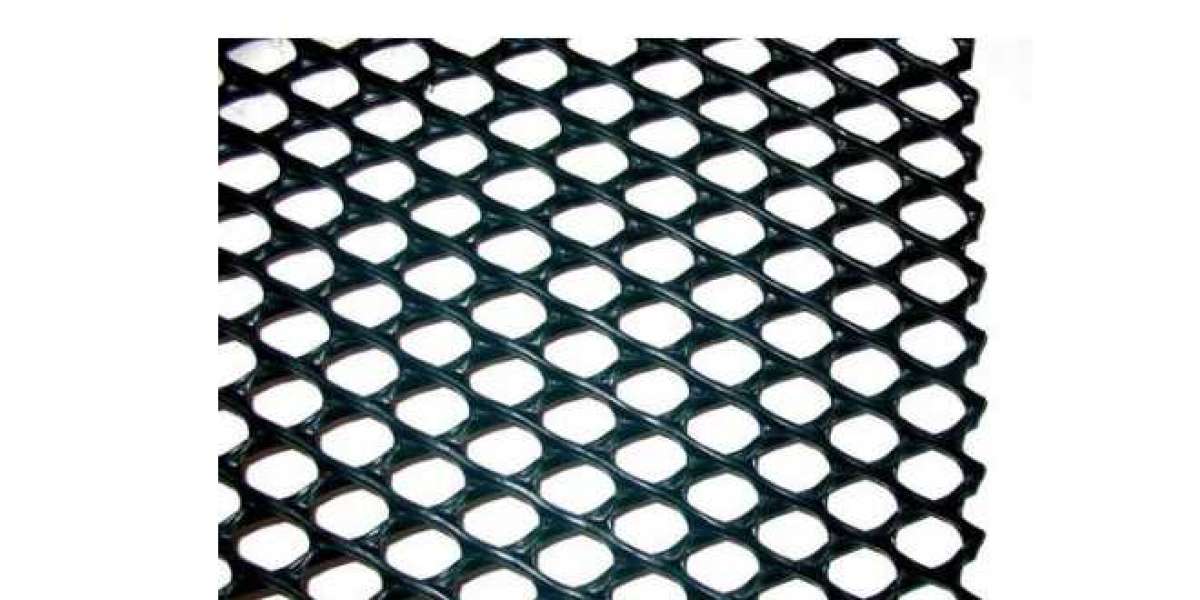

Geonet is a crucial component in geosynthetic materials, widely used in construction, drainage, and environmental protection applications. This post will provide a comprehensive guide on geonets, their benefits, applications, and frequently asked questions.

What is Geonet?

Geonet is a synthetic material made from high-density polyethylene (HDPE) or other polymers, designed to provide efficient drainage Pulkit Plastic Products and filtration. It consists of interconnected ribs that form a net-like structure, allowing the passage of fluids while offering structural stability.

How is Geonet Manufactured?

The manufacturing process of geonets involves:

Extrusion Process: HDPE is melted and extruded into continuous strands.

Forming a Grid Structure: The strands are arranged in a specific pattern to create a three-dimensional net-like structure.

Cooling and Cutting: The material is cooled and cut into required sizes and thicknesses.

Applications of Geonet

Geonet is widely used across various industries due to its excellent drainage and reinforcement properties.

1. Drainage Systems

Landfill Drainage

The Geonet in road construction are extensively used in landfills to manage leachate drainage, preventing groundwater contamination.

Road and Railway Drainage

They provide efficient drainage in roads and railways, reducing water accumulation and enhancing stability.

2. Erosion Control

Geonets are used in slope stabilization to prevent soil erosion, particularly in areas prone to heavy rainfall.

3. Geotechnical Engineering

Geonets are utilized for soil reinforcement in embankments, retaining walls, and bridge abutments.

4. Environmental Protection

Water Management

They help in managing stormwater by facilitating water flow in green infrastructure projects.

Mining Applications

Geonets are used in heap leach pads to enhance drainage efficiency and prevent toxic water accumulation.

Benefits of Using Geonet

Geonets offer numerous advantages in construction and environmental applications.

1. High Drainage Efficiency

Their open structure allows for rapid water flow, preventing waterlogging and soil instability.

2. Cost-Effective Solution

Compared to traditional drainage methods, geonets reduce material and labor costs while ensuring long-term durability.

3. Lightweight and Easy to Install

Geonets are lightweight and flexible, making them easy to transport and install without heavy machinery.

4. Chemical and Biological Resistance

Being made of HDPE, Geonets for highway construction are resistant to chemicals, UV rays, and biological degradation, ensuring longevity.

Choosing the Right Geonet

When selecting a geonet, consider the following factors:

Load-Bearing Capacity – Ensure it can withstand the expected load.

Thickness and Rib Design – The design impacts drainage efficiency.

Environmental Conditions – Choose a material that resists UV exposure and chemicals.

Conclusion

Geonets play a vital role in modern engineering and environmental management. With their superior drainage capabilities, cost-effectiveness, and long lifespan, they offer a reliable solution for various applications. Whether for landfill drainage, erosion control, or geotechnical engineering, Geonet use in road engineering are a smart choice for sustainable infrastructure development.

FAQs

1. What is the primary purpose of geonet?

Geonets are primarily used for drainage and reinforcement applications in construction, landfill management, and environmental protection.

2. Can geonet be used in extreme weather conditions?

Yes, geonets are designed to withstand extreme weather conditions, including heavy rainfall, freezing temperatures, and high UV exposure.

3. How long does a geonet last?

With proper installation and maintenance, geonets can last for decades, offering long-term efficiency and durability.

4. Is geonet environmentally friendly?

Yes, geonets are made from recyclable materials and help in environmental protection by managing waste and preventing soil erosion.