Tiotropium, a bronchodilator, is a crucial medication used in the treatment of chronic obstructive pulmonary disease (COPD) and asthma. With its increasing demand in the pharmaceutical industry, understanding the production cost of Tiotropium has become a priority for manufacturers, investors, and procurement managers. This comprehensive report covers various aspects of Tiotropium production, including the cost model, pre-feasibility analysis, industrial trends, labor charges, utilities, logistics, and the supply chain, offering a thorough analysis of all factors that impact its cost.

Tiotropium Production Cost: Understanding the Basics

The production cost of Tiotropium is influenced by multiple factors, from the raw materials required for its synthesis to the various operational costs of its manufacturing. The cost structure includes both fixed and variable costs, making it essential for manufacturers to optimize their operations to stay competitive in the market. A proper understanding of these factors is vital to calculate the Tiotropium production cost accurately.

Cost Model: Breakdown of Production Expenses

The cost model for Tiotropium involves several components, such as raw materials, labor, utilities, equipment, overhead, and distribution costs. Let’s take a closer look at each of these components.

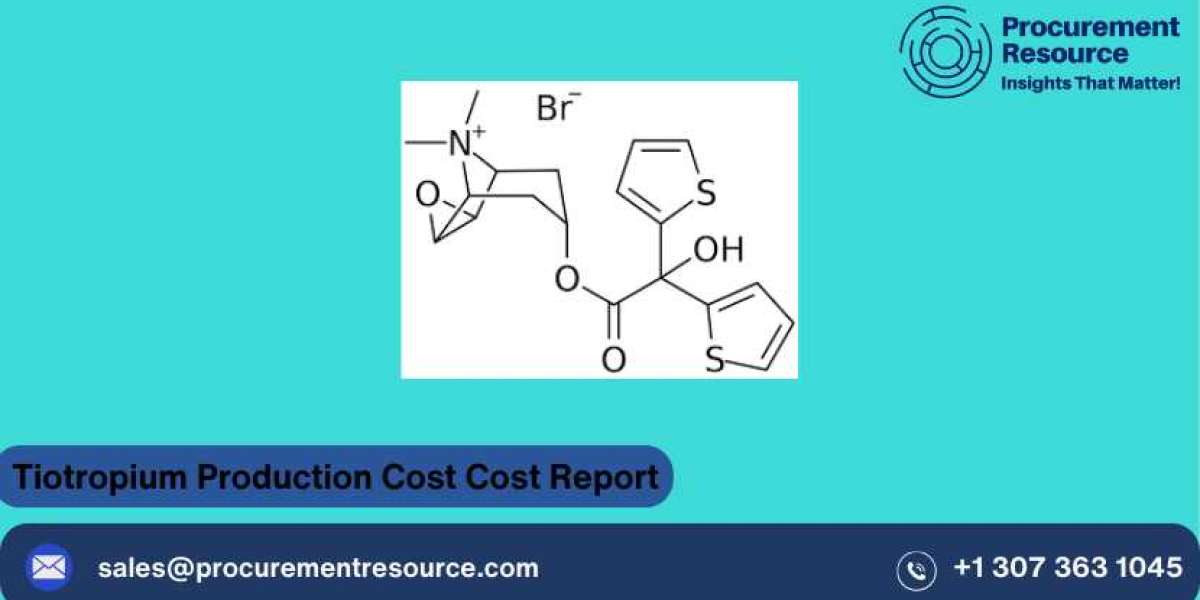

Raw Materials: The synthesis of Tiotropium requires high-quality raw materials like chemicals and reagents that undergo multiple chemical reactions to produce the final product. The cost of these materials is one of the largest portions of the overall production cost.

Labor Charges: Labor costs for Tiotropium production involve salaries for skilled workers, including chemists, technicians, and support staff. Labor charges also account for the time spent on production processes and quality control. The labor rate varies depending on the location of the manufacturing facility and the skills required.

Utilities: Utilities such as electricity, water, and gas are essential for pharmaceutical production, and they contribute significantly to the overall Tiotropium production cost. These utilities are used for chemical reactions, maintaining temperature and humidity levels, and providing necessary energy to manufacturing equipment.

Equipment and Machinery: Manufacturing Tiotropium requires specialized equipment, such as reactors, mixers, and drying machines, to ensure the product meets the required standards. The depreciation and maintenance of this equipment, along with the cost of spare parts, add to the production cost.

Overhead and Miscellaneous Costs: These include facility maintenance, administrative expenses, and research and development (RD) costs. Overhead costs are incurred in maintaining production facilities, regulatory compliance, and staff training.

Request a Free Sample - https://www.procurementresource.com/production-cost-report-store/tiotropium/request-sample

Pre-feasibility Study: A Vital Aspect of Tiotropium Production

Before any production facility can begin producing Tiotropium, a pre-feasibility study must be conducted to assess the viability of the project. This study evaluates factors such as market demand, availability of raw materials, regulatory requirements, capital investment, and operational efficiency.

Key considerations include:

Market Demand and Supply: A thorough understanding of the demand for Tiotropium in various regions, such as North America, Europe, and Asia, helps determine whether it’s financially viable to invest in a production facility.

Regulatory Approvals: Tiotropium production requires strict compliance with pharmaceutical industry regulations, including those set by the FDA and EMA. A pre-feasibility study evaluates the time and costs required for obtaining necessary approvals.

Capital Investment: The initial investment in setting up a Tiotropium production facility can be substantial. The pre-feasibility study helps to determine the expected return on investment (ROI) and break-even points.

Technology and Expertise: Assessing the availability of technology and skilled labor is also essential for ensuring efficient production. Companies often have to invest in advanced manufacturing processes to keep pace with industry trends.

Industrial Trends Impacting Tiotropium Production Cost

As the pharmaceutical industry continues to evolve, several industrial trends influence the cost of Tiotropium production. These include:

Advances in Manufacturing Technologies: Technological advancements, such as continuous manufacturing and automated production systems, are reducing production costs by increasing efficiency and reducing human error.

Outsourcing and Contract Manufacturing: Many companies are turning to contract manufacturing organizations (CMOs) to reduce the overhead costs associated with building and maintaining their own production facilities.

Sustainability Practices: With increasing environmental concerns, pharmaceutical companies are adopting sustainable practices in Tiotropium production. This includes reducing waste, recycling chemicals, and implementing energy-efficient processes, which can lower long-term production costs.

Global Supply Chain Dynamics: The global pharmaceutical supply chain is subject to various external factors, including geopolitical instability, trade regulations, and transportation costs, all of which can affect Tiotropium production costs. Manufacturers must adapt to these challenges to maintain cost-effectiveness.

Labor Charges in Tiotropium Manufacturing

Labor costs are a significant component of the overall production cost. The need for specialized personnel such as chemists, operators, and quality control specialists makes labor charges an ongoing concern for manufacturers. Labor charges also include training costs for employees to ensure that production standards are met, as well as the costs associated with recruitment and retention.

The labor charges may vary depending on the region, with countries like India and China offering lower labor costs compared to North America and Europe. Companies may choose to set up production facilities in regions with lower labor costs to achieve cost savings.

Utilities and Their Impact on Tiotropium Production

Utilities are essential for the pharmaceutical manufacturing process, and Tiotropium production is no exception. The consumption of utilities such as electricity, water, and gas is a recurring cost for manufacturers. The cost of utilities depends on local pricing, usage efficiency, and the type of energy sources used. Energy-intensive processes, such as drying and chemical synthesis, can significantly drive up utility expenses. Manufacturers are exploring renewable energy sources and energy-saving technologies to lower utility costs.

Logistics and Supply Chain Considerations

Efficient logistics and supply chain management are crucial for reducing Tiotropium production costs. The supply chain includes the procurement of raw materials, transportation, inventory management, and distribution of the final product to customers. Delays in raw material delivery or disruptions in the transportation network can increase costs and affect the timely availability of the product.

Manufacturers can optimize their supply chain by partnering with reliable suppliers, utilizing advanced forecasting tools, and investing in efficient transportation systems. Strategic warehouse management can also help in minimizing storage costs.

Request a Free Sample

For a deeper understanding of the Tiotropium production cost analysis and the factors that impact it, we offer a free sample of our comprehensive report. This sample will provide you with detailed insights into cost breakdowns, production models, and industrial trends.

Request Your Free Sample Report - https://www.procurementresource.com/production-cost-report-store/tiotropium/request-sample

Procurement Resource: Your Partner in Cost Analysis

At Procurement Resource, we specialize in providing in-depth market research, cost models, and feasibility reports across various industries, including pharmaceuticals. Our reports help businesses make informed decisions and optimize production costs. Whether you're looking to understand the complexities of Tiotropium production or need a detailed market trend analysis, Procurement Resource is your go-to partner.

Contact Us:

Company Name: Procurement Resource

Contact Person: Tom Hanks

Email: sales@procurementresource.com

Toll-Free Number: USA Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA