Understanding Uniaxial Geogrids

Uniaxial geogrids are polymeric materials designed primarily for soil reinforcement applications. They consist of a grid-like structure that provides support and stability, particularly in applications such as retaining walls, slopes, and foundations. The benefits of using uniaxial geogrids include improved load distribution, reduced settlement, and overall enhanced durability.

As the demand for uniaxial geogrids continues to rise, so does the importance of identifying reliable suppliers. Choosing the right Uniaxial geogrid manufacturer and suppliers can make a significant difference in the outcome of your project.

Key Factors to Consider When Sourcing Uniaxial Geogrids

1. Quality Assurance

The foremost consideration when sourcing uniaxial geogrids is quality. A reliable uniaxial geogrid manufacturer should adhere to ASTM and ISO standards to ensure their products meet international quality benchmarks. Requesting certification and testing reports from potential manufacturers can provide insight into the quality of the geogrids. Look for manufacturers who can demonstrate their products have undergone rigorous quality control processes.

2. Material Specifications

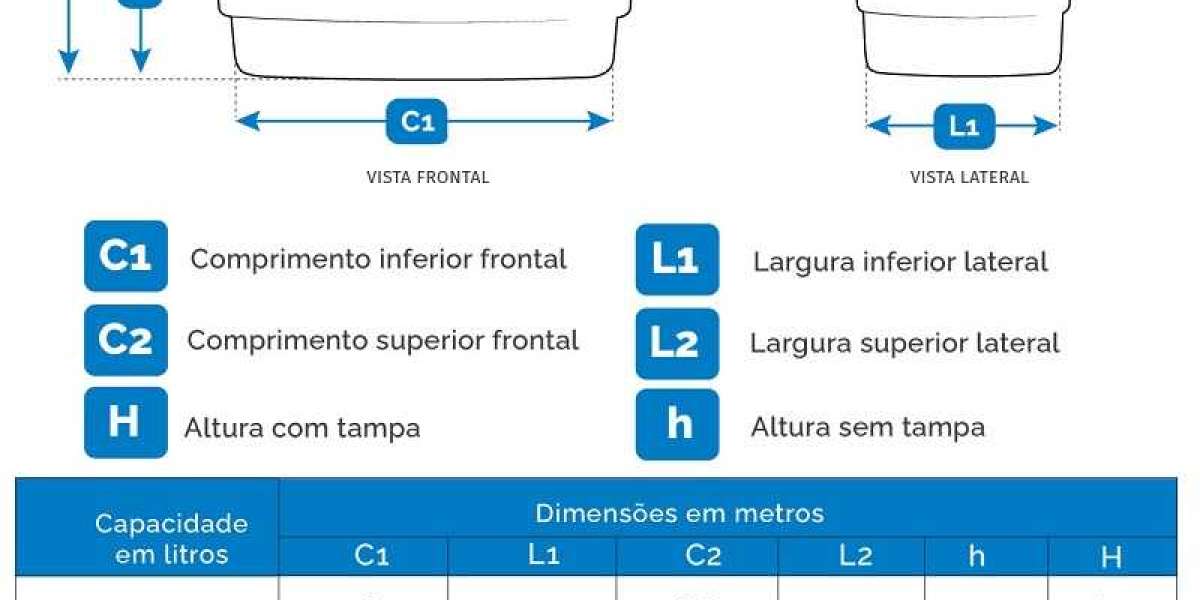

Understanding the specifications of uniaxial geogrids is essential for ensuring they meet project requirements. Factors such as material type, tensile strength, elongation at break, and environmental resistance play crucial roles in the performance of the geogrid. Manufacturers should provide detailed product specifications and be transparent about the materials used in their products.

3. Performance Indicators

Evaluating the performance of uniaxial geogrids through laboratory testing is vital. Tests such as pull-out resistance, creep behavior, and stress-strain characteristics will give insight into how the geogrid will behave under load. Seek suppliers willing to provide empirical evidence of their products' performances to assure you of their reliability in real-world applications.

4. Experience and Reputation

The track record of the manufacturer is another essential factor. Established Uniaxial geogrid suppliers with extensive experience in the industry tend to have more reliable products. Research the reputation of potential suppliers by checking customer reviews, case studies, and references. Speak to other clients who have previously worked with the supplier to gauge their service quality and product performance.

5. Geographical Considerations

When sourcing uniaxial geogrids, it's vital to consider the location of the manufacturer or suppliers. Sourcing from local uniaxial geogrid suppliers can not only reduce transportation costs but also deliver products more quickly. In India, for instance, several established uniaxial geogrid manufacturers offer competitive pricing and services, contributing to a more streamlined procurement process.

6. Customer Support and Service

Excellent customer service should not be overlooked. A supplier that provides responsive and knowledgeable support can facilitate a smoother sourcing process. Ensure that your chosen manufacturer or supplier is committed to assisting you throughout the project, from initial inquiries to after-sales support. It’s beneficial to work with manufacturers who understand construction challenges and can provide solutions quickly.

7. Customization and Flexibility

Every project is unique, and having a manufacturer capable of offering customized uniaxial geogrid solutions can be a significant advantage. Discuss your project requirements with potential suppliers, and inquire about their willingness to develop products tailored to your needs. Flexibility in design will ensure that you receive a product that aligns perfectly with your specific project demands.

8. Cost Evaluations

While cost is undoubtedly a consideration, it should not be the sole factor in your decision-making process. Low costs may sometimes indicate subpar quality, which could lead to greater expenses later through project failure or delays. Seek a balance between cost and quality to ensure you are getting value for your investment. Ask for detailed quotations that encompass costs for materials, shipping, and potential installation.

9. Compliance with Regulations

Compliance with local building codes and regulations is a must when sourcing geogrids. Manufacturers should be well-versed in these regulations to ensure that their products can be safely used in your area. Verify if the products meet environmental and safety regulations applicable to your project, as this can save you time and resources down the line.

Final Thoughts

Sourcing Uniaxial geogrid in India is a pivotal step in ensuring the success of your engineering and construction projects. By prioritizing quality, understanding specifications, verifying performance, considering geographic location, valuing customer support, and ensuring compliance, you can mitigate risks associated with underspecified or faulty materials.

India is burgeoning with opportunities for sourcing uniaxial geogrids, given the presence of reputable uniaxial geogrid manufacturers and suppliers committed to delivering quality products. Take the time to research and evaluate potential partners, using the tips discussed in this article to inform your sourcing decisions. Ultimately, informed choices will lead to enhanced performance, reducing long-term costs, and safeguarding the integrity of your construction endeavors.

Frequently Asked Questions (FAQs)

Where can I find uniaxial geogrid suppliers in India?

You can find uniaxial geogrid suppliers across India by searching online directories, industry trade shows, and networking within construction and civil engineering circles. Local suppliers often have the advantage of faster delivery times.

What are the benefits of using uniaxial geogrids?

The benefits of uniaxial geogrids include enhanced load-bearing capacity, improved soil stabilization, cost-efficiency through reduced material usage, and ease of installation.

How do I know if a uniaxial geogrid is of good quality?

Look for manufacturers that provide detailed product specifications, certifications, and customer reviews. Testing samples can also provide insights into the material's performance and durability.